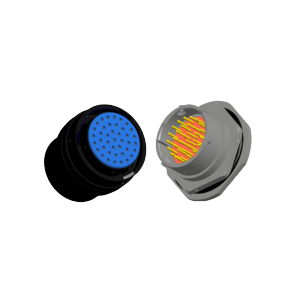

YQ2 series Circular Electrical Connector

Environmental Specifications

| Operating temperature | -55 to +125°C | Sinusoidal Vibration | 10 ~ 50 Hz, single amplitude 2 mm

50 Hz ~ 2000 Hz, 196 m/s2 |

| Working pressure | 101.3kPa ~ 1.1kPa | ||

| Relative humidity | 40± 2℃ @ 90% ~ 95% | Fungus | GJB150.10A, class 2 |

| Mechanical life | 500 cycles | Shock | 392 m/s2, 10 ms 980 m/s2, 3 ms |

| Rain fall | 5 mm/min | Hermetic Seal | Ordinary Seal≥ 196 KPa Glass sintering seal ≤1×10-5 Pa.L/s |

Electrical specifications

- Contact resistance and rated current

| No. of Contacts | 20# | 16# | |

| Contact diameter (mm) | 1.04 | 1.61 | |

| Rated Current (A) | 5 | 10 | |

| Contact resistance (mΩ) | Ordinary contacts | ≤ 5 | ≤ 3 |

| Glass sealing | ≤ 15 | ≤ 10 | |

- Rated voltage, withstand voltage and insulation resistance

| Working Environment | Withstand Voltage (Vrms) | Insulation Resistance (MΩ) |

| Normal Temperature and pressure | 1500 | ≥ 3000

Glass sealing≥1000 |

| High temperature and humidity | 1000

Glass sealing: 500 |

≥ 20 |

| High temperature | — | ≥ 500 |

| Low air pressure | 500

Glass sealing: 250 |

— |

Mechanical specifications

| Housing Material | Aluminum alloy and Stainless steel | Insulator Material | Thermoplastic |

| Housing Plating | Ordinary anodizing for Aluminum alloy

Additional code c: Nickel plated Aluminum alloy Additional code d: Electropolishing |

Contact material/ plating |

Copper alloy/Gold plated Kovar alloy/ Gold plated |

Order mark

Example: YQ2Ha II-18 32 ZJ14-2ed

| YQ2 | H | a | II | – | 18 | 32 | Z | J | 14 | – | 2 | e | d | |

| Basic Series No. | YQ2 | |||||||||||||

Category No.

|

H | |||||||||||||

Shell Position No

|

a | |||||||||||||

Insulator Position No.

|

II | |||||||||||||

Shell No.

|

18 | |||||||||||||

Contact arrangement

|

32 | |||||||||||||

Connector type

|

Z | |||||||||||||

Contact type

|

J | |||||||||||||

Mounting type

|

14 | |||||||||||||

Separator

|

– | |||||||||||||

Cable cover type

|

2 | |||||||||||||

Contact part end connection form

|

e | |||||||||||||

Additional Code

|

d |

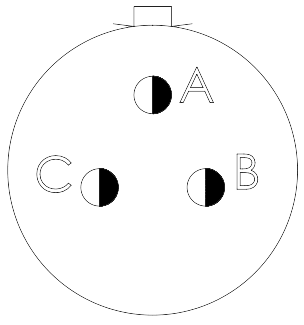

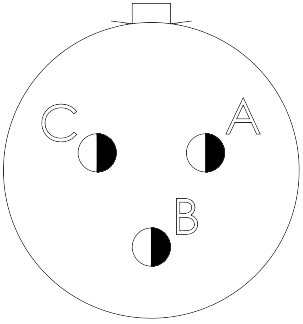

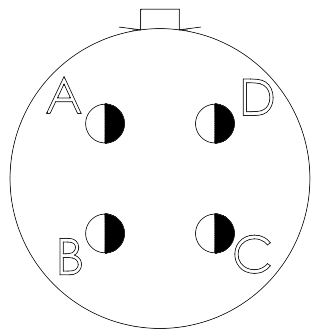

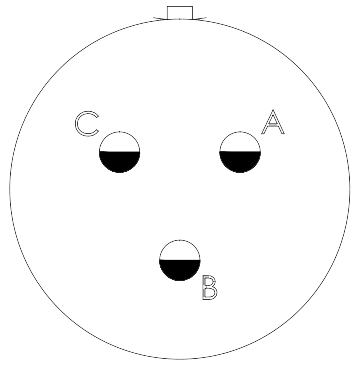

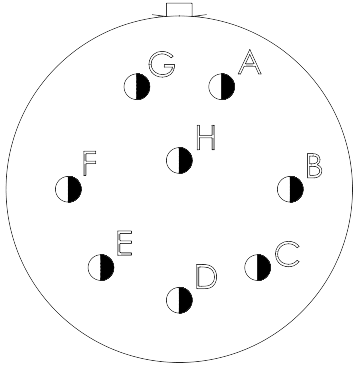

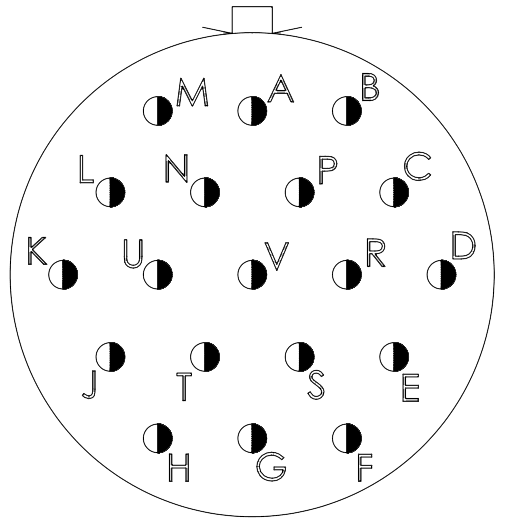

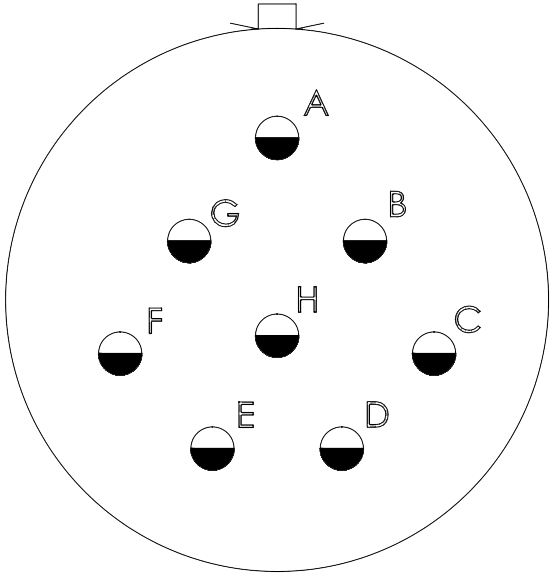

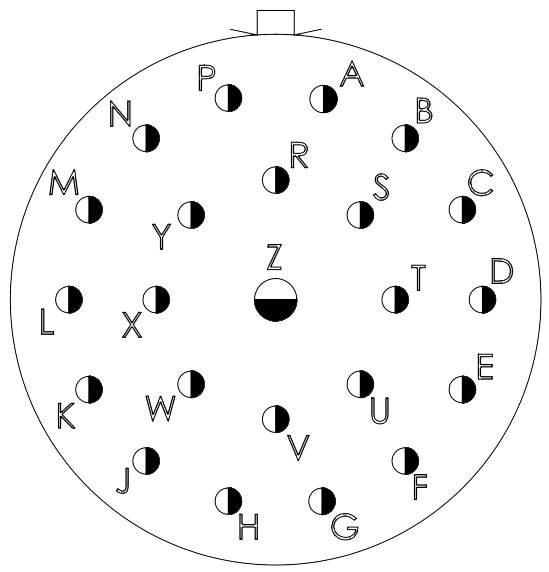

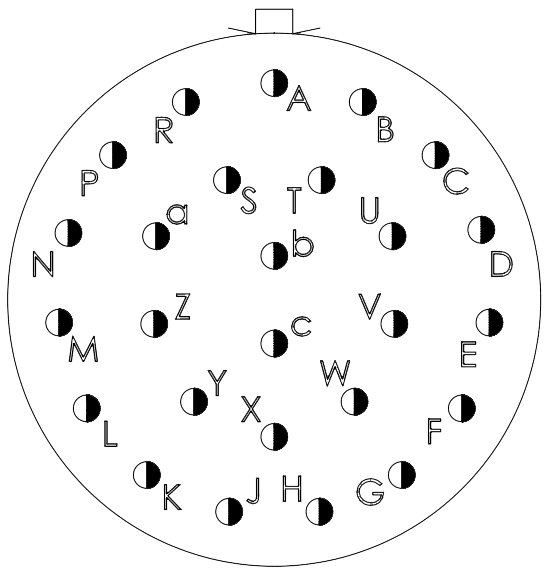

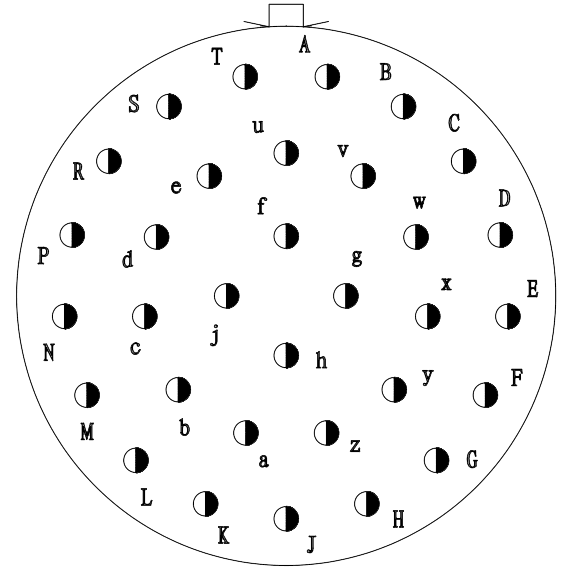

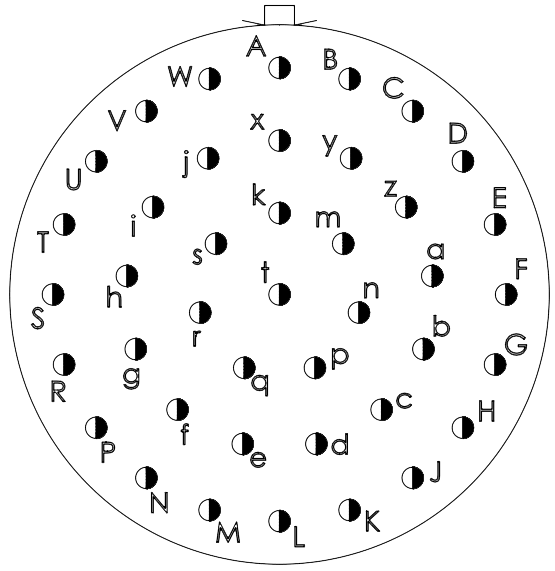

YQ2 Contact arrangement

| Contact specifications |  |

|

| 20# | 16# |

|

|

|

|

|

|

| 0803 | 0803I | 0804 | 1203 | 1208 | 1419 |

|

|

|

|||

| 1608 | 1623 | 1626 | |||

|

|

||||

| 1832 | 2041 | ||||

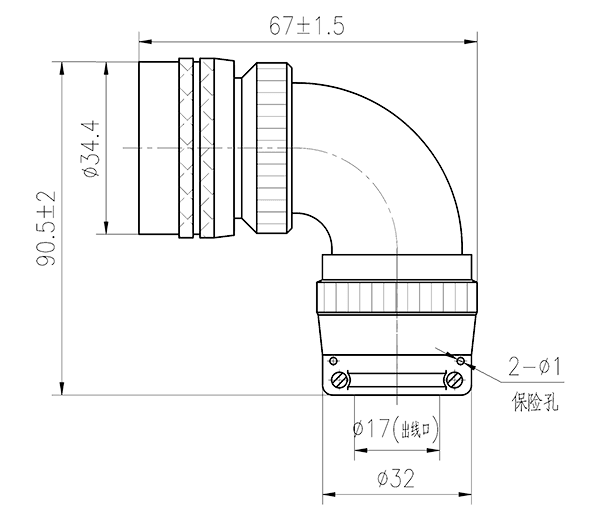

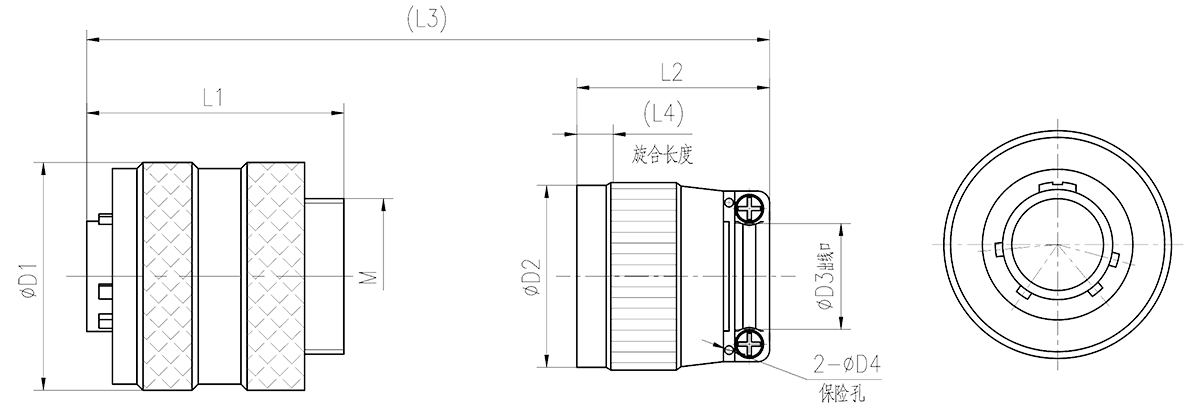

Drawings

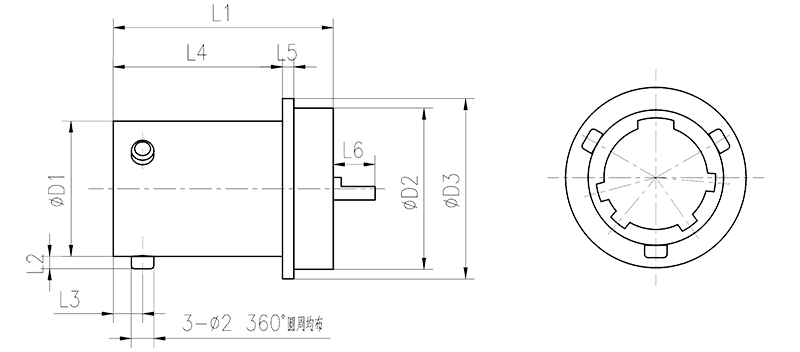

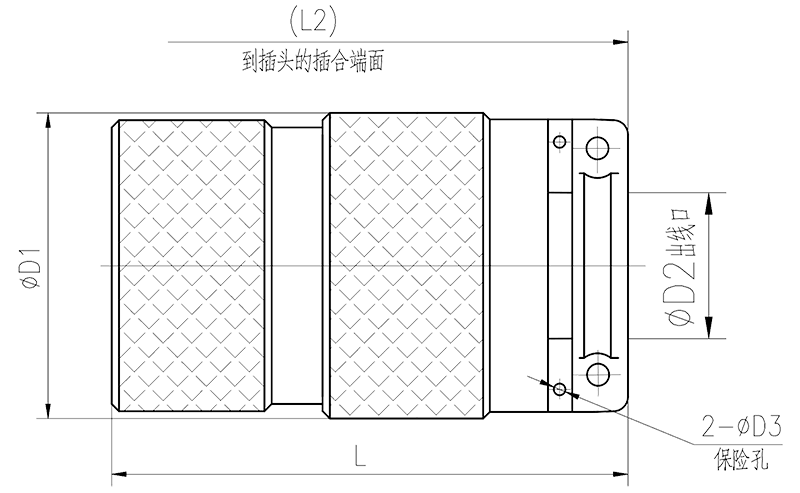

- Plug

|

|||||||||

| Shell No. | D1 | D2 | D3 | D4 | L1 | L2 | L3 | L4 | M |

| 08 | 18.6 | 15 | 6 | 0.8 | 21 | 20 | 36 | 5 | 1/2-28 |

| 12 | 25.6 | – | – | – | 21 | – | – | – | 11/16-24 |

| 14 | 25.6 | 25.5 | 10 | – | 21 | 30 | 46.4 | 4.6 | 13/16-20 |

| 16 | 31.7 | 30 | 12.6 | – | 21 | 32 | 48.4 | 4.6 | 15/16-20 |

| 18 | 34.4 | 32 | 17 | 1 | 21 | 28 | 44.4 | 4.6 | 1 1/16-18 |

| 20 | 37.7 | 35 | 20 | 1.5 | 25 | 30 | 49 | 6 | 1 3/16-18 |

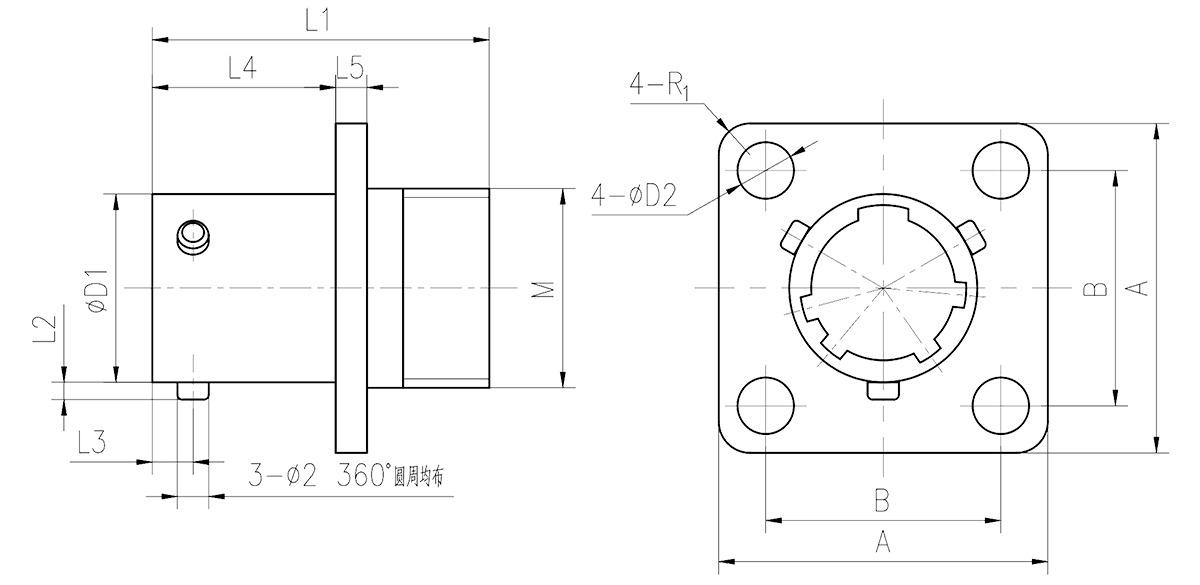

- Square Flange Receptacle

|

|||||||||||

|

Shell No. |

A | B | D1 | D2 | L1 | L2 | L3 | L4 | L5 | M (in) | R1 |

| 08 | 21 | 15±0.15 | 12 | 3.6 | 21.5 | 1.1 | 2.6 | 11.7 | 2 | 1/2-28 | 2 |

| 12 | 26.2 | 20.6±0.16 | 19 | 3.2 | 21.5 | 1.2 | 2.6 | 12 | 2 | 11/16-24 | Φ35 |

| 14 | 28.5 | 23±0.16 | 22.3 | 3.2 | 21.5 | 1.2 | 2.6 | 12 | 2 | 13/16-20 | Φ38 |

| 16 | 31 | 24.6±0.16 | 25.4 | 3.2 | 21.5 | 1.2 | 2.6 | 12 | 2 | 15/16-20 | Φ41.4 |

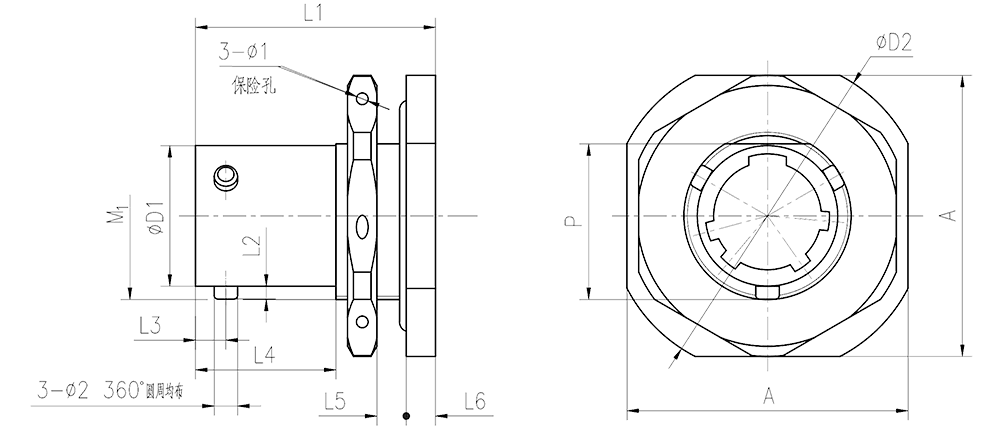

- Round Flange Receptacle

|

|||||||||

| Shell No. | D1 | D2 | D3 | L1 | L2 | L3 | L4 | L5 | L6 |

| 0803 | 12 | 14.3 | 16 | 19.5 | 1.1 | 2.6 | 15 | 1 | 3.8 |

| 0804 | 12 | 13 | 15 | 15 | 1.1 | 2.6 | 11 | 1 | 5.3 |

- Nut Mounting Receptacle

|

|||||||||||

| Shell No. | A | P | D1 | D2 | L1 | L2 | L3 | L4 | L5 | L6 | M (in) |

| 8 | 24 | 13.3 | 12 | 27 | 20.5 | 1.1 | 2.6 | 12 | 1.5-3.2 | 2.5 | 9/16-24 |

| 12 | 32 | 20.6 | 19 | 35.2 | 23 | 1.2 | 2.6 | 12 | 1.5-4 | 3.2 | 7/8-20 |

| 16 | 38.2 | 27 | 25.4 | 41.4 | 23 | 1.2 | 2.6 | 12 | 1.5-4 | 3.2 | 1 1/8-18 |

| 18 | 41 | 30.5 | 28.5 | 44.4 | 20.5 | 1.2 | 2.2 | 10 | 1.5-4.7 | 2.5 | 1 1/4-18 |

| 20 | 46 | 33.5 | 31.8 | 49 | 25 | 1.2 | 2.5 | 11.4 | 1.8-7.3 | 3 | 1 3/8-18 |

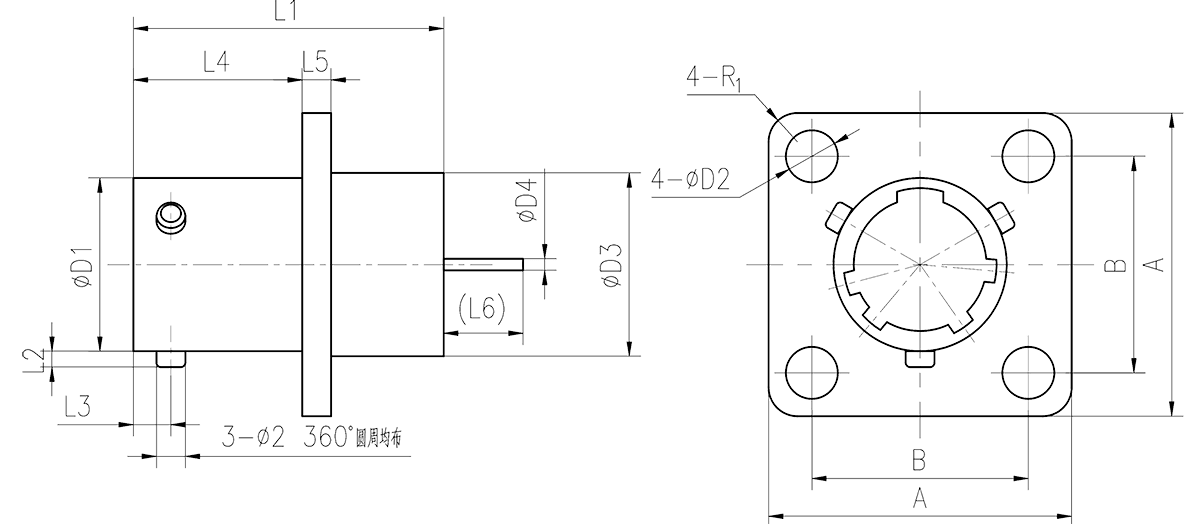

- PCB Mounting Receptacle

|

|||||||||||||

| Shell No. | A | B | D1 | D2 | D3 | D4 | L1 | L2 | L3 | L4 | L5 | L6 | R1 |

| 08 | 21 | 15±0.15 | 12 | 3.6 | 12.7 | 0.8 | 21.5 | 1.1 | 2.6 | 11.7 | 2 | 5.5 | 2 |

| 12 | 26.2 | 20.6±0.16 | 19 | 3.2 | 17.4 | 0.8 | 21.5 | 1.2 | 2.6 | 12 | 2 | 5.5 | Φ35 |

| 14 | 28.5 | 23±0.16 | 22.3 | 3.2 | 20.6 | 0.8 | 21.5 | 1.2 | 2.6 | 12 | 2 | 5.5 | Φ38 |

| 16 | 31 | 24.6±0.16 | 25.4 | 3.2 | 23.8 | 0.8 | 21.5 | 1.2 | 2.6 | 12 | 2 | 5.5 | Φ41.4 |

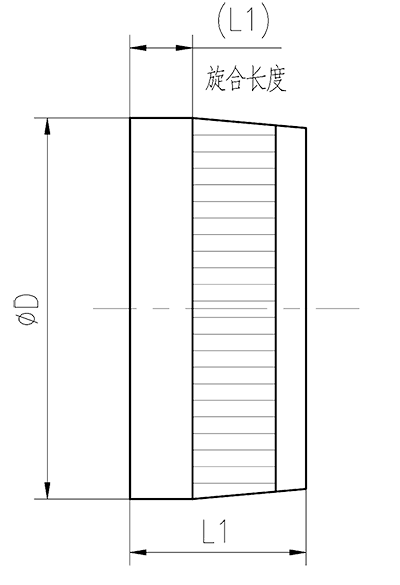

- Attachment

|

|

|||||||||

| Nut Type Cable Cover | Shielded Cable Cover | |||||||||

| Shell No. | D | L1 | L2 | Shell No. | D1 | D2 | D3 | L1 | L2 | |

| 16 | 26.2 | 13.3 | 4.8 | 08 | 18 | 8 | 0.8 | 29 | 45 | |

| 18 | 29.2 | 13.5 | 4.8 | 14 | 30 | 16 | 0.8 | 43 | 58 | |

| 20 | 32.4 | 17.2 | 7.1 | |||||||

- 18# shell bent plug